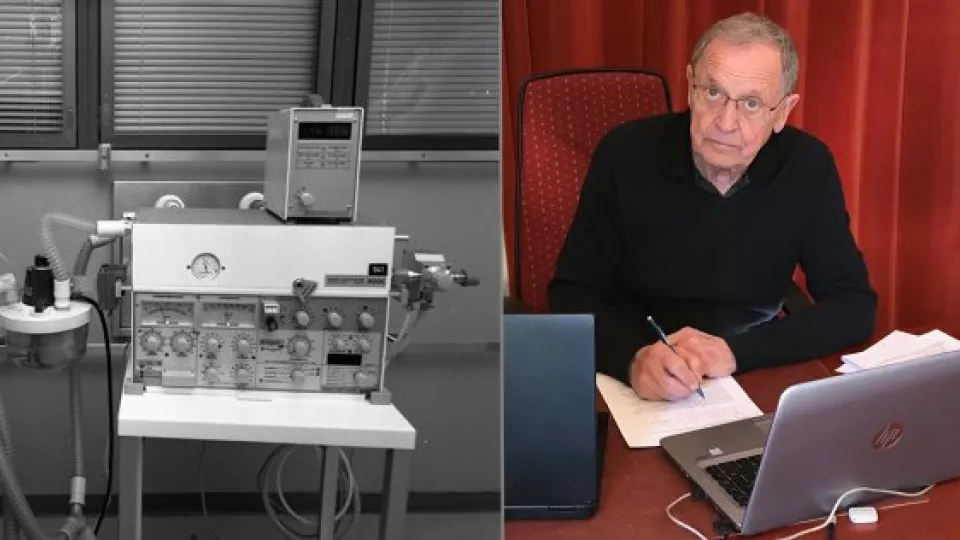

Björn Jonson has worked as a researcher in pulmonary physiology since the beginning of the 1960s. Quite early on in his research, he realised that the equipment for respiratory support at the time was inadequate. Together with his colleague Sven Ingelstedt, he developed the modern-day ventilator – the servo ventilator – that became hugely significant for intensive care around the world.

And now he is going to do it again: he is developing a ventilator specifically adapted to the treatment of patients with COVID 19 in intensive care who require respiratory support to survive. It involves ventilation and oxygenating the blood, pressing air into the lungs and then releasing it. It is a balancing act to not damage the lungs, which can happen if the pressure fluctuations are too great. It is also about providing support at the right time.

“Following appeals and requests for help from colleagues in hard hit countries, I woke up in the middle of the night three days ago and realised I had to try to do something. The situation around the world is indescribably horrible, with thousands and thousands of people dying because there is not enough equipment. There is an enormous need for equipment to provide respiratory support”, says Björn Jonson.

That night, Björn Jonson decided to take on the challenge of trying to develop a new ventilator. Barely a day later he was sitting in a meeting with a representative for a Swedish multinational company discussing what is required. It involves equipment in large numbers, which can be used by many people.

“Ventilators are complex and expensive pieces of equipment that require specialist skills. The new ventilator must have certain characteristics that make it easier to use. It needs to be extremely easy to operate with only limited vital functions that also need to work extremely well. There cannot be any compromises whatsoever when it comes to the treatment principle. In addition, it needs to cost a lot less than what such equipment usually costs.”

Based on this, Björn Jonson’s development work is now underway. It involves producing requirement specifications for the ventilator, finding the right components, which must be possible to manufacture quickly and on a large scale, as well as a thorough analysis of all other factors (economic, technical, legal etc.) that are required to move from ideas to action. And it must happen quickly.

“On a daily basis, I am receiving reports from colleagues around the world about the dreadful dilemmas they are facing. Patients with high and intractable fevers, who have respiratory problems and whose lungs are exposed to extreme pressure fluctuations while they are fighting for life. There is a lack of resources in the hard hit countries and healthcare staff are forced to wait until the last moment to use a ventilator. Then, it is often too late. Therefore, we need to quickly develop enough equipment and provide information on when it is to be used in the disease process.”

The current situation in Sweden is not quite as critical as in many other countries, but things could turn quickly for the worse and there may be a lack of various resources here as well, not least in healthcare material. Within healthcare all over Sweden, people are preparing themselves as best they can. The situation is changing from day to day.

When it comes to the development of the new ventilator, Björn Jonson is hopeful. What concerns him is the matter of permits.

“Pharmaceuticals and medical equipment must, of course, go through a number of clinical trials, tests etc. before they are approved by the European Medicines Agency. However, this takes time, time we do not have. In this situation, extra support and investment are required for us to bring this project to fruition.”

There is a significant need for healthcare material due to the rapid development of the number of patients with the coronavirus disease COVID 19. Many staff and students at Lund University want to help and are taking great initiatives to support healthcare in different ways. One of these great initiatives was taken by David Nordlund, researcher at the Cardiac MR group at the Department of Clinical Physiology at Lund University.

“It feels very important right now that we all take responsibility and contribute as much as we can. Within research, we have access to a number of ventilators and, firstly, we have carried out an inventory of how many ventilators we have and, secondly, we are working on getting them in a condition so they can be used in healthcare. We have then reported this to the intensive care unit at Skåne University Hospital so they are aware of the extra resources we can provide”, says David Nordlund.

The Cardiac MR group at Lund University now has five respirators/ventilators that are available as back-up for Skåne University Hospital but other units within the Faculty of Medicine have also carried out inventories that have been reported to the healthcare system.

Rapid development of ventilator for COVID 19

‘With age comes wisdom’ is an old proverb well suited to Björn Jonson, professor emeritus in clinical physiology who is about to turn 80. He is working day and night to develop a ventilator specifically adapted to the treatment of those suffering the most from COVID 19.

Latest news

Categories